BOD Manager Example Calculations

The Hach WIMS BOD Manager utilizes the following calculations to perform the BOD method. The method consists of filling an airtight bottle with a sample. The bottle is a specified size and filled to overflowing. The sample is incubated at constant temperature for five days. Dissolved oxygen (D.O.) is measured by probe before and after incubation. BOD is computed based on the difference between initial and final D.O.

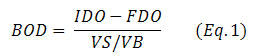

The test uses dilution water and a known amount of sample in a 250-300 ml incubation bottle. A small amount of seed is added to samples where microbial activity may not be present. The initial D.O. is measured by probe and the bottle is stored at 20 °C. After five days, final D.O. is measured. If no seed is used, the BOD of the bottle is computed using Equation 1.

where:

IDO = initial D.O. of diluted sample, mg/L

FDO = final D.O. of diluted sample, mg/L

VS = volume of sample, ml

VB = volume of bottle, ml

BOD = biochemical oxygen demand, mg/L

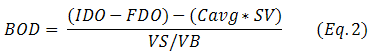

When seed is added, seed control tests must be done to determine the amount of oxygen depleted by the seed. Calculation of BOD includes a correction factor for seed as expressed by Equation 2.

where:

IDO = initial D.O. of diluted sample, mg/L

FDO = final D.O. of diluted sample, 0 mg/L

VS = volume of sample, ml

VB = volume of bottle, ml

Cavg = correction factor for oxygen depletion resulting from presence of seed

SV = Volume of Seed added to Sample in ml.

BOD = biochemical oxygen demand, mg/L

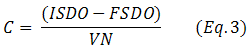

The correction factor for a bottle of Seed is derived using Equation 3.

where:

C = correction factor for oxygen depletion resulting from presence of seed

ISDO = initial D.O. for seed control test N

FSDO = final D.O. for seed control test N

VN = volume of seed used in control test N

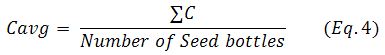

The Seed Corrections (mg/L) per ml of seed added is then calculated:

I.E. Seed Correction (mg/L) per ml of seed added is the average of all non-marked correction factors for the Seed Sample.

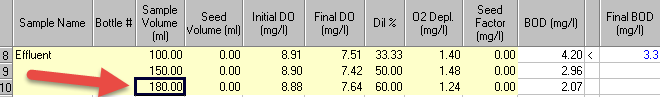

The Final BOD is calculated by averaging all non-marked (i.e. bottles that pass the criteria) bottles for the sample. The Final BOD is stored in the associated WIMS variable (see BOD Manager Sample Setup)

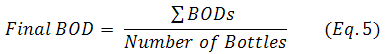

Example 1: Unseeded BOD

300 ml bottles are used

Bottle #10 BOD = (8.6 - 5.2) / (6/300) = 3.4/ 0.02 = 170

The Final BOD = (170 + 142.50 + 129) / 3 = 147.17

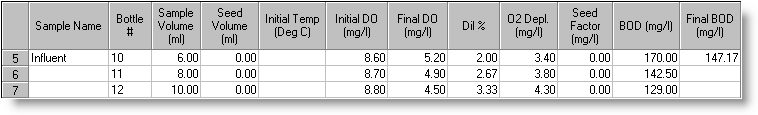

Example 2: Seeded BOD

Calculate the Effluent BOD which is seeded with the Sample named "Seed".

The first step is to calculated the Seed Correction per ml of seed added. Therefore we need to calculated the Seed bottles first:

Seed Correction per ml using equation 3:

Bottle 110: (8.9 - 5.8) / 10 = 3.1 / 10 = 0.31

Bottle 111: (8.94 - 5.7) / 12 = 3.24 / 12 = 0.27

Therefore the Seed Corrections (mg/L) per ml of Seed added = (0.31 + 0.27) / 2 = 0.29

To calculate the BOD for Effluent bottle 210 using equation 2:

((8.7 - 5.3) - (3 * 0.29)) / (200 / 300) = (3.4 - 0.87) / .6667 = 2.53 / .6667 = 3.8

Final BOD for the Effluent Sample is the average of valid (unmaked) BOD's for bottles 210, 211, 212 :

Therefore it is (3.8 + 3.64) / 2 = 7.44/2 = 3.72 ===> 4 when rounded to zero decimal places as specified for Effluent BOD in Edit/View Variables.

Note: Bottle 212 was NOT used in the average because it was marked due to invalid Final DO (Final DO must be 1.0 or greater as specified in Criteria Setup).

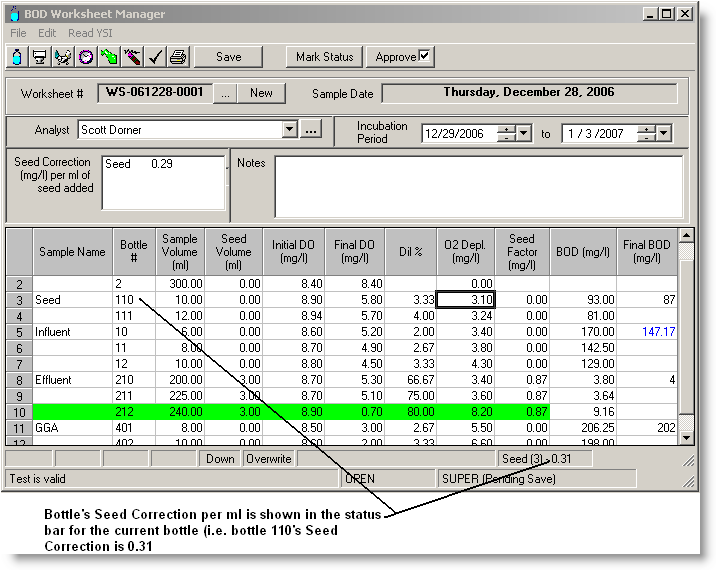

Example 3: All Depletions <2 use 2 and report as < on:

With If all Depletions in Sample are <2 use 2 and report as less than set to on in BOD Manager Criteria Setup.

If all dilutions (bottles) in a sample have a depletion (i.e. Initial minus Final DO) that is not at least 2 mg/L, select the dilution (bottle) with the greatest Sample Volume, calculate the BOD using a depletion of 2 and report as <.

The following 3 dilutions are run and none of the dilutions has a depletion of 2. Therefore, we use the dilution with the greatest Sample Volume, 180 ml on row 10 and assume a depletion of 2.

BOD = (2) / (180/300) = 2 / 0.6 = 3.3333

We use 2 instead of 1.24 in the calculation. It is rounded to 1 decimal place as defined in Sample Setup and Variable Setup and the Final BOD is reported as <3.3.

NOTE: If bottles are seeded the seeding is ignored in the calculation if all values have a depletion less than 2.

Example 4: Coefficient of Variation Criteria check

The Coefficient of Variation (CV) check is used to detect and mark bottles that are outliers in the sample.

CV = Standard Deviation / Average

In the example below:

- Standard Deviation of 3.78, 3.92, 8.77 = 2.8414

- Average of 3.78, 3.92, 8.77 = 5.49

- CV = 2.8414 / 5.49 = 0.5176

Since 0.5176 > CVLimit of 0.35 we apply the following rules to mark a bottle.

Calculate the CV of the 2 lowest BODs (3.78 and 3.92)

- Low CV = SD/AVG = 0.098994 / 3.85 = 0.0257

Calculate the CV of the 2 highest BODs (8.77 and 3.92)

- High CV = SD/AVG = 3.4295 / 6.345 = 0.5405

Apply the rules:

If LowCV < CVLimit And High CV < CVLimit Then

Mark Lowest BOD Bottle 'rule 7B

ElseIf High CV < CVLimit Then

Mark Lowest BOD Bottle 'rule 7C

ElseIf LowCV < CVLimit Then

Mark Highest BOD Bottle 'rule 7C

Else

Mark All Bottles 'rule 8

Endif

If One bottle is marked we then check the CV of the 2 remaining bottles.

- CV = 0.0257

- If CV > CVLimit mark the Lowest BOD of the 2.

In this example, we mark the Highest BOD Bottle: