| Edit/View Variables - Quality Control Tab |

|

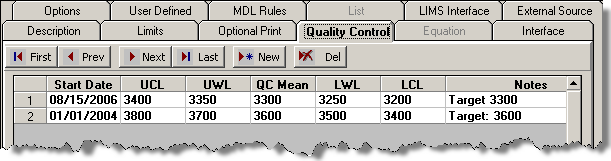

Quality Control Limits for a variable can be defined. The QC Limits are used throughout OPS SQL in Time Series Graphs, Spread Reports, QC Analysis Report...

FIELDS:

Start date: The start date for the Limit.

UCL: Upper Control Limit. Typically calculated as the Mean +3 Standard Deviations of the variable for a period of time when the process is determined to be in control. 99.7% of values should be below this line.

UWL: Upper Warning Limit. Typically calculated as the Mean +2 Standard Deviations of the variable for a period of time when the process is determined to be in control. 95% of values should be below this line.

QC Mean: Typically the target. Is the average of values when the process is determined to be in control.

LWL: Lower Warning Limit. Typically calculated as the Mean -2 Standard Deviations of the variable for a period of time when the process is determined to be in control. 95% of values should be above this line.

LCL: Lower Control Limit. Typically calculated as the Mean -3 Standard Deviations of the variable for a period of time when the process is determined to be in control. 99.7% of values should be below this line.

BUTTONS:

|

Used to create a new limit. Inserts a new row to be filled out. |

|

Deletes the currently selected limit or limits. |

NOTES:

EXAMPLES: